Services

What we do

We stand for excellence and expertise. From product development and manufacturing to packaging, testing and final shipment of goods, we deliver everything from a single source, offering the perfect end-to-end solution for our customers. New products are accompanied and supported by our professional transfer team until they transition into safe routine operation.

We are happy to meet specific customer requests. Furthermore, we work on continuous product improvement in close collaboration with the customer.

With efficient, validated processes and a robust organisational structure, we always guarantee high-quality, reliable products.

Product development

We impress our customers with the development of customised, innovative products that set you apart from your competitors. As a CDMO (Contract Development and Manufacturing Organization), we develop novel, needs-based solutions and formulations, using conventional as well as new and modern technologies. Alongside formulation development, we also handle the development and validation of analytical methods, ICH (Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use) stability studies, dossier preparation and clinical batch manufacturing in a cGMP (Current Good Manufacturing Practice) environment.

Thanks to strong integration and technological alignment, we can guarantee our customers a seamless and secure transition from product development to industrial production.

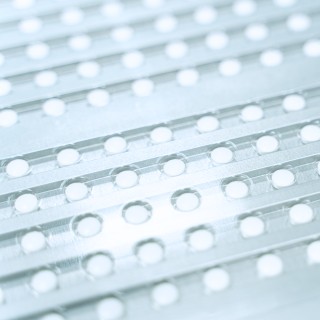

Capsules

Another core competence at our site is the flexible and efficient filling of hard gelatine capsules. We have the right process technology to produce every conceivable hard gelatine capsule formulation. Our high-performance capsule filling machines offer the best conditions for the highest pharmaceutical standards. The dosing systems are optimally configured for the product to be filled, whether it is powders, (mini) tablets, pellets, granules or various combinations in hard-shell capsules (Hydroxypropylmethylcellulose (HPMC) or gelatine). High-precision weighing modules, sensors and control systems ensure high product quality. Our experts from the development team are happy to support you in the process development.

Tablets

Tablets are the most common and important dosage form in all pharmaceutical markets. At Medinsa, tablets are also the most frequently produced form of medicine; last year alone, 612 million units were produced. Starting from a good compressible granulate or powder mixture, we produce a variety of different tablet forms, each of which is optimally tailored to specific drug treatments. In addition to film-coated and sustained-release tablets, common variations manufactured by us include special forms such as chewable, orally disintegrating, buccal and effervescent tablets. More advanced forms, such as mini- or microtablets and MUPS (Multiple Unit Pellet Systems) produced from pellets, are also part of our highly diversified range of services.

Pellets and MUPS

Pellets are produced using different methods depending on the starting materials and requirement profile. The most common process is layering. Here, the active substance is applied layer by layer onto neutral starter pellets in the form of a solution, suspension or powder. The active substance-coated core is then covered with various protective layers. This can achieve sustained release as well as gastric acid resistance. Alternatively, the pellets can be produced through extrusion and spheronisation. In this case, a granulate containing the active substance is wet extruded, crushed and then rounded to form pellets. After drying and sieving, these pellets are then coated with the appropriate protective layers to achieve effects such as sustained release and gastric acid resistance.

After completion, the pellets are filled into capsules or sachets. Further processing into MUPS (Multiple Unit Pellet Systems) tablets is also possible. This process involves compressing the pellets with powdered excipients. Undoubtedly, this technology belongs to the top tier in the processing of pellets.

Effervescent tablets

The range of applications for effervescent tablets is very diverse, including for flu remedies, cough relievers, vitamins or painkillers. The water-soluble effervescent tablets are not only pleasant for children but also for the elderly and patients with difficulty swallowing or sensitive stomachs. While effervescent tablets offer many advantages for consumers, the hygroscopic pharmaceutical form is challenging to manufacture and process. Effervescent tablets are large, weighing two to five grammes, and are naturally prone to air entrapment and undesirable capping. Their tabletting is therefore done step by step with increasing compression force, often involving external spraying with magnesium stearate, which acts as a lubricant. Due to their high fragility, the delicate tablets must be filled and packed directly into plastic tubes under dry room conditions.

Impressions

Our everyday work

On our production area of 6,300 square metres, we currently process around 90 active substances into more than 650 different finished goods. Each year, we deliver a total of just over 21 million finished product packages.

Quality control

Our robust IT-supported quality management system (QMS) is the basis of our daily work in all GxP (Good Practice)-relevant areas. The system is continuously inspected, both internally and externally, and is continuously refined and improved to ensure its effectiveness.

Our QMS (Quality Management System) is built on innovation, digitalisation and continuous improvement. It strengthens the connection between development and manufacturing activities throughout the entire product lifecycle, from development and manufacturing to product shipment. Our QMS includes monitoring and implementation of industry trends and new regulatory requirements, frequent reviews of our processes and products, monitoring key quality indicators, risk assessments, quality management reviews, audits, inspections and self-inspections. The insights gained from these processes contribute to the development of our quality strategy, ensuring a robust and continuous level of quality.

In our state-of-the-art laboratories, we rigorously verify the strict adherence to specifications and standards of our raw materials and finished products. All testing is done in-house by our qualified and well-trained staff. This also applies to microbiological testing and hygiene monitoring.

Our Services

What we also do

In addition to pharmaceutical manufacturing, we place special emphasis on development. We see ourselves as an extended workbench for Aristo Pharma and our third-party customers. Our highly efficient full-service approach supports new pharmaceuticals from conception and formulation to post-marketing production.

In addition to pharmaceutical manufacturing, we place special emphasis on development. We see ourselves as an extended workbench for Aristo Pharma and our third-party customers. Our highly efficient full-service approach supports new pharmaceuticals from conception and formulation to post-marketing production.

Contact

Are you looking for a contract manufacturer? Get in touch with us.

Do you have questions about our services, would you like advice or a quote? Then get in touch with us. We are available to you at any time by phone or email.